Low suction pressure high subcooling – Low suction pressure and high subcooling are common issues in refrigeration systems that can lead to reduced efficiency, increased energy consumption, and even system damage. Understanding the causes, consequences, and troubleshooting procedures for these conditions is crucial for maintaining optimal system performance.

This comprehensive guide will delve into the causes and consequences of low suction pressure and high subcooling, providing practical troubleshooting tips and preventive maintenance strategies to ensure the longevity and efficiency of your refrigeration system.

Low Suction Pressure and High Subcooling

Low suction pressure and high subcooling are common issues that can arise in refrigeration systems. These conditions can indicate a variety of problems, ranging from refrigerant leaks to system blockages. It is important to be able to identify and troubleshoot these issues in order to maintain optimal system performance and prevent further damage.

Causes of Low Suction Pressure and High Subcooling: Low Suction Pressure High Subcooling

Potential Refrigerant Leaks

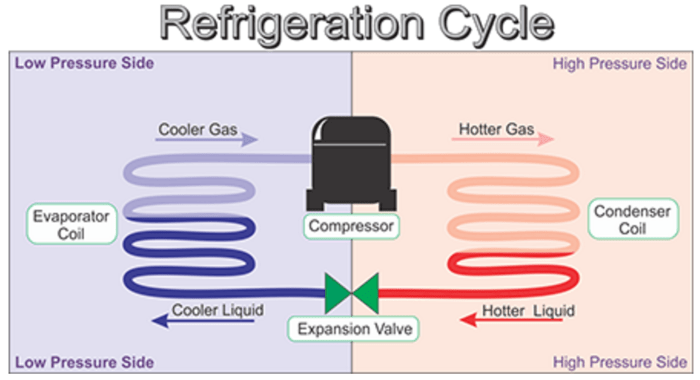

Refrigerant leaks are one of the most common causes of low suction pressure and high subcooling. When refrigerant escapes from the system, it reduces the amount of refrigerant available to absorb heat, which in turn leads to lower suction pressure.

Additionally, the loss of refrigerant can cause a decrease in the system’s capacity, which can further contribute to high subcooling.

Possible System Blockages

System blockages can also lead to low suction pressure and high subcooling. Blockages can occur in any part of the system, including the evaporator, condenser, or lines. When a blockage occurs, it restricts the flow of refrigerant, which can lead to a drop in suction pressure and an increase in subcooling.

Metering Device Malfunctions

Metering devices are responsible for regulating the flow of refrigerant into the evaporator. If a metering device malfunctions, it can either restrict the flow of refrigerant or allow too much refrigerant to enter the evaporator. Both of these conditions can lead to low suction pressure and high subcooling.

Consequences of Low Suction Pressure and High Subcooling

Impact on Compressor Operation

Low suction pressure and high subcooling can have a significant impact on compressor operation. When suction pressure is low, the compressor has to work harder to pull refrigerant into the system. This can lead to increased wear and tear on the compressor, as well as a decrease in its efficiency.

Effects on System Capacity

Low suction pressure and high subcooling can also affect the system’s capacity. When suction pressure is low, the compressor is unable to circulate as much refrigerant through the system. This can lead to a decrease in the system’s cooling capacity.

Potential for System Damage, Low suction pressure high subcooling

If left unchecked, low suction pressure and high subcooling can lead to serious damage to the refrigeration system. The compressor can overheat and seize, the evaporator can freeze, and the system can lose its charge of refrigerant.

Troubleshooting and Repair Procedures

Troubleshooting Checklist for Low Suction Pressure and High Subcooling

- Check for refrigerant leaks.

- Inspect the system for blockages.

- Check the metering device for proper operation.

- Measure the suction pressure and subcooling.

- Compare the readings to the manufacturer’s specifications.

Repair Methods for Refrigerant Leaks

- Use a leak detector to locate the leak.

- Repair the leak by soldering or brazing.

- Recharge the system with refrigerant.

Procedures for Clearing System Blockages

- Identify the location of the blockage.

- Remove the blockage by blowing it out with compressed air or using a chemical cleaner.

- Flush the system with refrigerant to remove any remaining debris.

Techniques for Diagnosing and Repairing Metering Device Issues

- Check the metering device for proper operation.

- Replace the metering device if it is found to be faulty.

- Adjust the metering device to the manufacturer’s specifications.

Preventive Maintenance Strategies

Tips for Preventing Refrigerant Leaks

- Inspect the system regularly for leaks.

- Tighten all fittings and connections.

- Use leak-proof sealant on all joints.

- Handle refrigerant cylinders carefully.

Methods for Avoiding System Blockages

- Use a filter drier to remove moisture and contaminants from the system.

- Clean the condenser coils regularly.

- Flush the system with refrigerant every few years to remove any debris.

Importance of Regular System Maintenance

Regular system maintenance is essential for preventing low suction pressure and high subcooling. By following the preventive maintenance tips Artikeld above, you can help to keep your refrigeration system running efficiently and reliably.

Answers to Common Questions

What are the common causes of low suction pressure?

Refrigerant leaks, system blockages, and metering device malfunctions are the most common causes of low suction pressure.

What are the consequences of high subcooling?

High subcooling can lead to reduced system capacity, compressor damage, and increased energy consumption.

How can I troubleshoot low suction pressure and high subcooling?

Check for refrigerant leaks, inspect for system blockages, and diagnose metering device issues using a troubleshooting checklist.

What preventive maintenance strategies can I implement?

Regular system inspections, leak detection, and proper refrigerant charging are crucial preventive maintenance strategies.